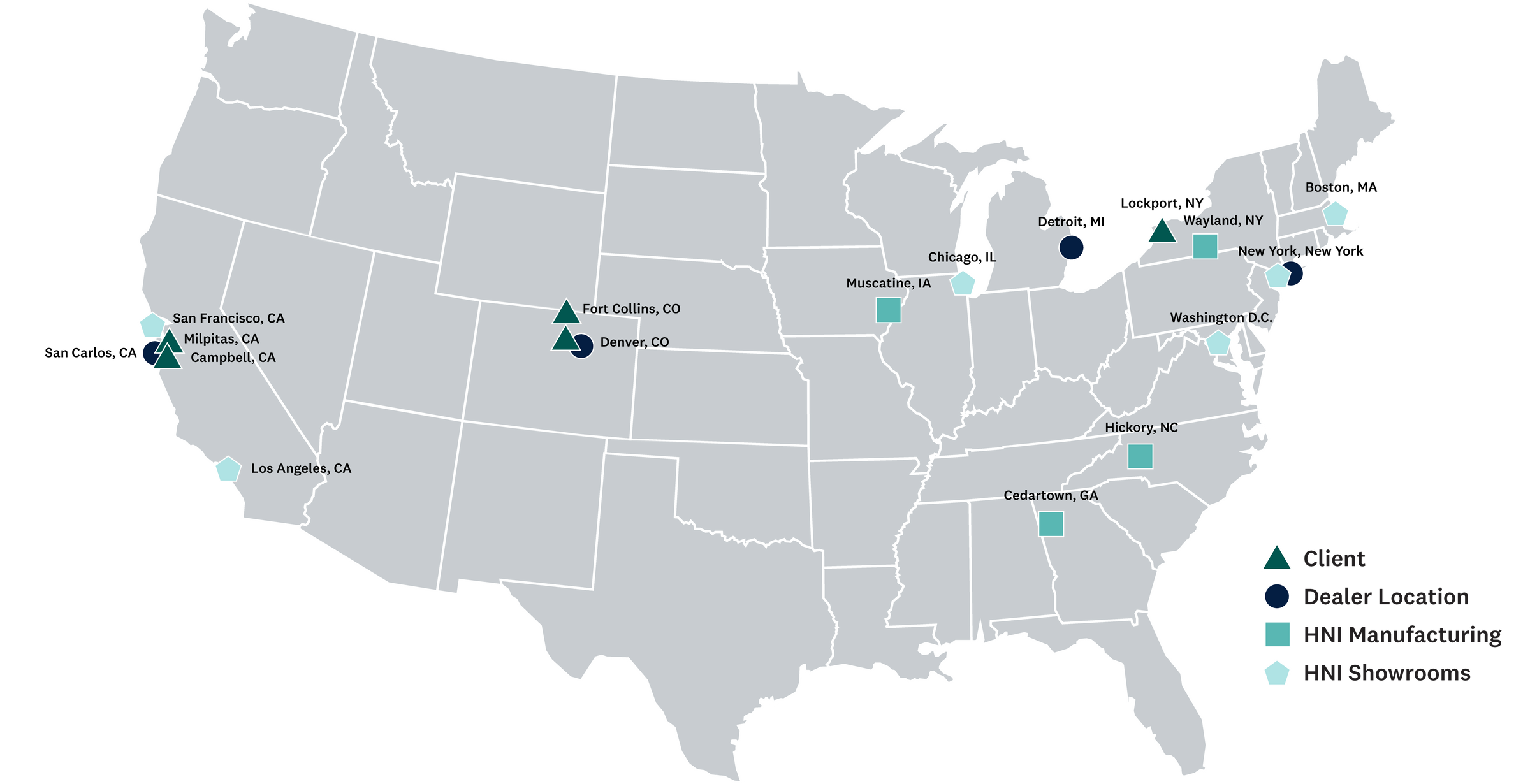

Helping clients work across the nation

NATIONAL Coverage

Order Management

Client Portal

Asset Management

Content Management

E-Business

Service and Request Tracking

Reporting

Exceptional Service At Any Scale, Anywhere

HNI’s Has State-of-the-Art Manufacturing Facilities Across the World

Equipment

- German automated laminate lines

- State-of-the-art paint lines

- Smart material handling

- Centralized environmental system

- Efficient consolidation of orders

- Improved loading bays

- Technology-powered production

Labor

- Follow International standards for health and safety

- Highly skilled workers

Product Quality

- Produced to ANSI/BIFMA standards

- Meets all local certifications

Supply Chain

We hold our suppliers to the same standards to which we hold our members—a commitment to maintain a culture of integrity, to treat others with fairness and respect, to be open, honest, and trustworthy, and to follow all laws and regulations. We outline these expectations in our Supplier Code of Conduct, which all suppliers must sign as part of our Annual Compliance process.

HNI values the diversity of our supplier relationships and do business with a wide range of suppliers, from global industry leaders to local and lean businesses aligned with our manufacturing locations. In the U.S., about 20 percent of HNI’s suppliers are designated Local Lean and Aligned (LLA) suppliers. These are businesses that deliver to our facilities multiple times a day. We work closely with these businesses to continuously improve supply chain processes including how inventory is stored, packaged, delivered, and returned. Our LLA suppliers help us to lower inventory and reduce floor space while also eliminating waste and unnecessary touch points and steps. For example, suppliers deliver parts in reusable racks, totes, and containers instead of corrugated boxes which members would have had to open, place into other containers, and then break down for disposal. Several of our LLA suppliers were started by former HNI members or include former members on their leadership teams.

Sometimes, the best supplier for a need or part is our own company and members. Through vertical integration, we strategically select some manufacturing processes to perform inhouse, such as plastic injection molding. Instead of purchasing certain plastic parts from a number of suppliers, we’ve started to source the raw material and create the parts ourselves. Vertical integration provides us with greater control of our supply chain, and a better understanding of materials, products, and design impacts. We’ve reduced transportation needs, packaging requirements, and touch points between part fabrication and assembly. And, we’ve created more skilled job opportunities for our members.